How It's Made

INNOVATIVE MEASURING TECHNOLOGY

The bespoke process starts with taking the measurements. Thanks to a scanning technology, Jacob Madani ensures to have the highest level of precision. During an individual appointment at our store, the feet are scanned while enjoying a relaxed atmosphere. Innovation is used hand in hand with craftsmanship. The work of the hand and manual techniques are leveraged with new devices.

MAKING YOUR UNIQUE LAST

The information collected is transferred to the workshops for the creation of a unique last. This model is the foundation of shoemaking and determines the shape. It is similar to a mannequin for the fashion designer, or a canvas for the painter. The last enables the shoe to fit its owner with precision and comfort. Traditionally, the last is wooden. At Jacob Madani, it is made of plastic-based on advanced scanning technology. What makes the brand unique, is that the last of each client is kept preciously and can be used for future bespoke orders.

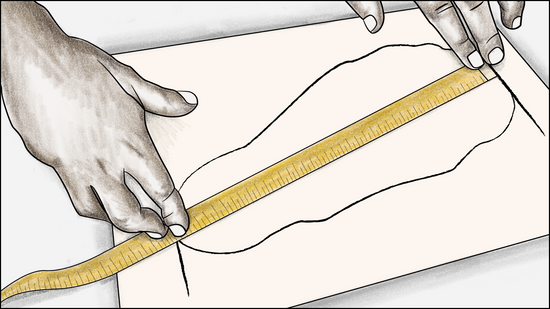

THE PRECISION OF THE CUT

Leather is cut following the designs of Jacob Madani and chosen by the client. The cutter uses the pattern carefully with experienced hands and selects the best parts of the leather. Supplied by close Italian and French partners, each piece of leather is of the highest quality.

THE ATTENTION TO SHAPE

Before mounting all the pieces together, great attention is given to perfecting the edges of the leather. Each part is made of materials of high quality that demands to be meticulously treated by skilled artisans.

PERFECTING THE DETAILS

The hands of the artisan complete the preparation of each piece before assembling. The heritage manual techniques used by previous generations of Jacob Madani’s family are handed down to every craftsman in the workshop and live through each detail and piece created.

SEWING WITH HIGH QUALITY THREADS

From leather cutting to stitching, each essential step is done by hand as well as innovative techniques. To tie the pieces together and make the shoe come to life, Jacob Madani use high-quality thread. For special items like watch straps, hand sewing is used with linen thread strengthened by bees wax. The smallest details are always those that make the biggest difference.

THE LASTING

Once all the pieces are ready, the assembling of each component can begin. The lasting of a shoe is one of the most exquisite steps. The artisan sees the piece come to life with a sculptural dimension. The meticulous work and expert know-how shows its final results.

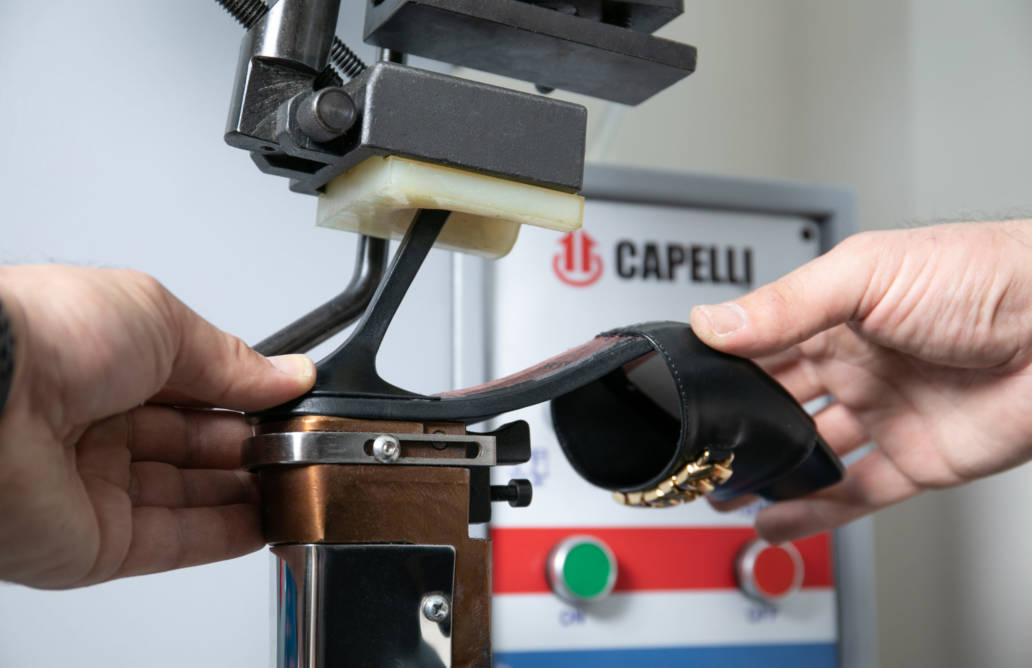

ADJUSTING THE BALANCE

The human hands are accompanied by innovative machinery for precision. The positioning of the heel is an essential step in the balance of the body. By carefully adjusting the sole and heel, the artisan makes sure the shoe guarantees the ideal allure for the silhouette.

THE FINISHING

The finishing appears once the shoe is fully made. The shoe is carefully verified before this essential step. When the piece is ready, the artisan brushes, polishes and waxes the leather to give it its unique luster and shine.

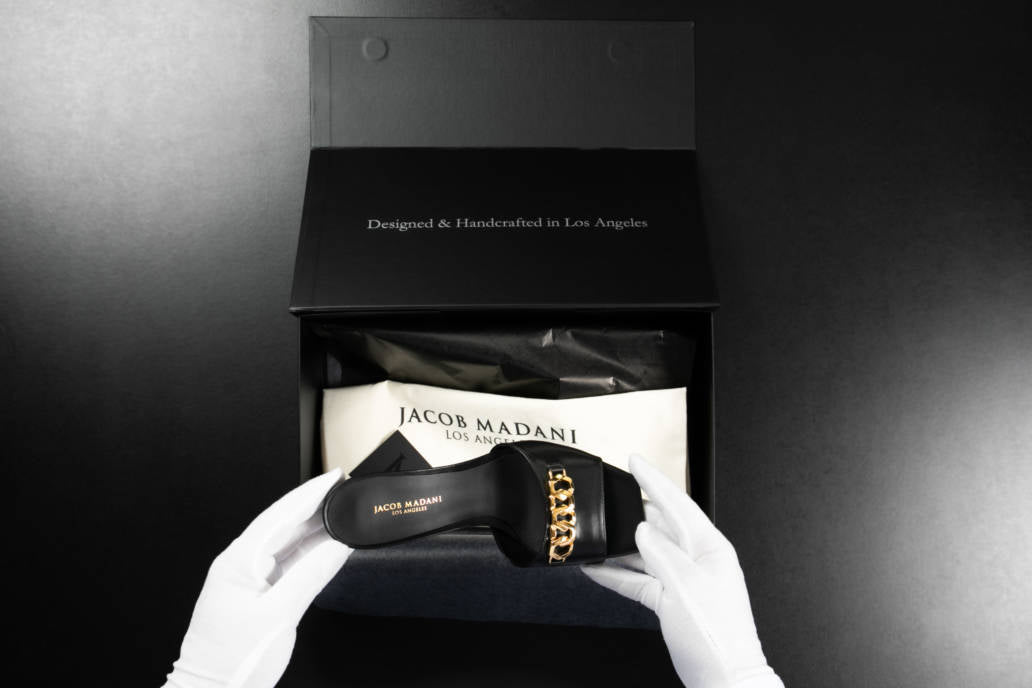

THE PACKAGING

The last step that adds Jacob Madani’s final touch to its creations is the packaging. The unique box has been designed following sophisticated and artistic inspirations to encapsulate the spirit of the brand. Each piece comes with a dust bag to protect the shoes and ensure their quality lasts through time.